- Home /

- Tooling /

- Broaching /

- PH Horn Type SH117 /

- SH117 C11 Tolerance Broaching Inserts

- 3D Printing Additive MFG

- CNC Machines in Stock

- Industrial Lubricants

- Machine Accessories

- Metrology

-

Tooling

- Broaching

- CK Boring System

- Counterbores

- Countersinks

-

Drills

-

Endmills

- Grooving & Part Off

-

Milling Bodies & Inserts

- BIG Fullcut 90 Degree 2 Edge Insert

- Korloy RM3 90 Degree 3 Edge Insert

- Sumitomo DFC 90 Degree 6 Edge Insert

- Sumitomo MSX High Feed Insert

- Sumitomo RSX Button Insert

- Sumitomo WAX Aluminium 2 Corner Insert

- Sumitomo WEX 90 Degree 2 Edge Insert

- Sumitomo WEZ 90 Degree 2 Edge Insert

- Sumitomo WFX 90 Degree 4 Edge Insert

- Sumitomo WRCX Button Insert

-

Milling Holders

- Reamers

-

Taps

- Threading

- Threadmills

-

Turning Holders

-

Turning Inserts

-

Workholding

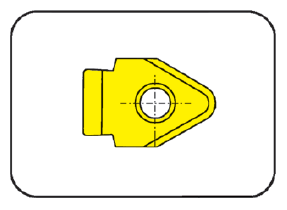

SH117 C11 Tolerance Broaching Inserts

PH HORN Type SH117 Broaching Tools

C11 Tolerance Inserts - TA45 Coated - For All Materials

Application Tips:

1) It is important to use a machine with mechanical spindle lock ie: C Axis on CNC Lathe

2) The use of proper coolant is key to a good surface finish, long tool life as well as good chip evacuation

3) A relief groove or the possibility for a "ramp down" exit out of the cut is necessary at the end of the broached groove

4) Setting of the tool is very important, double check the component diameter before taking the first pass

5) The tool should be set at the 12 O'Clock position to ensure that chips fall away from the groove

6) Take an accurate measurement of the insert and program the dimension into the machine tool parameter

7) Position the tool at the start position of the first stroke and program a stop to perform a visual check to assure a collision free pass of the tool!

The same Form must be used for Holder and Insert ie: Form C Holders can only fit Form C Inserts.